Description

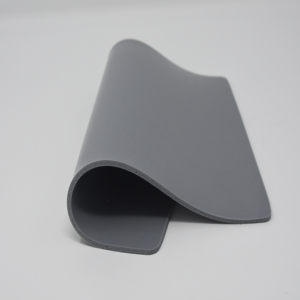

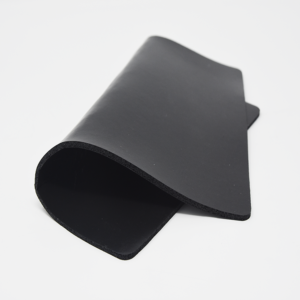

BISCO® HT-1500 Silicone Press Pad is a high-performance, fiberglass-reinforced solid silicone sheet designed to withstand extreme temperatures, pressure, and mechanical stress in industrial, aerospace, and high-precision manufacturing applications.

With superior tensile strength (52.5 kN/m / 300 ppi) and Shore A hardness of 70 ±10, BISCO® HT-1500 ensures consistent pressure distribution, durability, and thermal stability, making it ideal for press pads, composite molding, heat-sealing, and gasketing.

The reinforced silicone structure enhances dimensional stability and longevity, ensuring reliable performance in demanding environments. This AMS-3320-certified material meets aerospace and industrial quality standards, providing exceptional resistance to heat, compression, and chemical exposure.

Key Benefits of BISCO® HT-1500 Silicone Press Pad:

- Fiberglass reinforcement for enhanced strength and dimensional stability

- Exceptional heat resistance—ideal for high-temperature applications

- Uniform pressure distribution—ensures consistent results in lamination and molding

- Long-lasting durability—resists wear, compression, and mechanical stress

- Shore A hardness of 70 ±10—offers ideal flexibility and resilience

- AMS-3320 certified—meets aerospace and industrial safety standards

- Available in multiple thicknesses—customizable for specific applications

Common Applications:

- Silicone press pads for lamination and composite molding

- High-temperature industrial gasketing

- Heat-sealing and thermal insulation

- Aerospace and automotive component manufacturing

- Industrial applications requiring high-pressure resistance

💡 Available in thicknesses ranging from 0.787 mm (1/32″) to 3.175 mm (1/8″), with custom width tolerances for precision applications. Available for Die-Cutting and Lamination.